The United States is experiencing a surge in demand for distribution transformers, a critical component of its power infrastructure. This demand spike is not merely a localized issue; it reflects broader economic dynamics and necessitates a deeper understanding of its implications. Let’s delve into the economic intricacies of this phenomenon and its far-reaching impacts.

A POWERful Economic Contribution: The Multiplier Effect

The power, distribution, and specialty transformer manufacturing industry plays a pivotal role in the U.S. economy, with a significant multiplier effect. This effect surpasses both the average and median for all U.S. industries. There are two main reasons behind this robust multiplier effect:

- High Input Purchases and Employee Compensation: The industry exhibits high levels of input purchases and employee compensation per dollar of output. Approximately 65% of output is allocated to input purchases, while 27% goes to employee compensation. This dynamic results in a lower proportion of output going toward profits and taxes on production and imports, neither of which stimulate additional rounds of spending.

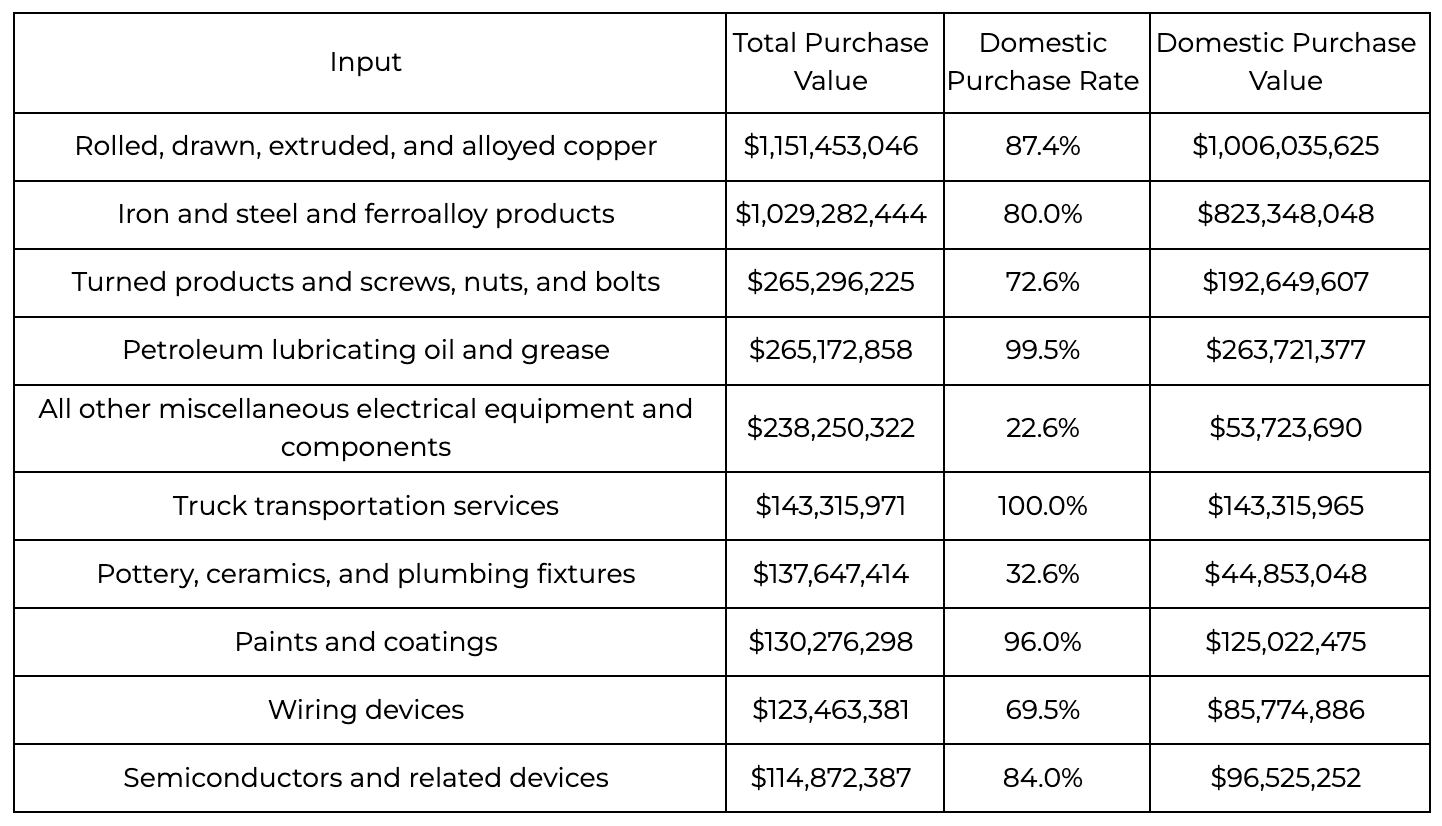

- Domestic Sourcing: The industry relies heavily on domestic sourcing for many of its key inputs, including copper, iron, steel, and various electrical components (see chart below). This reliance on domestic suppliers amplifies the industry's economic impact within the U.S.

Top 10 inputs of the Power, distribution, and specialty transformer manufacturing industry

Economic Impacts of Increased U.S. Production

The National Renewable Energy Laboratory (NREL) estimates that the current stock of distribution transformers in the U.S. ranges between 60-80 million, with installed capacity exceeding 3 terawatts. Projections suggest a substantial increase in stock capacity by 2050, indicating a pressing need for additional transformers to meet escalating demand.

The escalation in demand has led to a significant rise in transformer prices. Reports indicate a surge from $3,000-$4,000 per transformer before the shortage to more than $20,000 in 2022. An article by Copper Development Association Inc. puts the cost per transformer at half that – at roughly $10,000. Despite variations in reported costs, there's a consensus on the substantial increase in transformer expenses.

Assuming moderate estimates for the current stock, capacity growth, and cost per transformer, the production of an additional 77 million transformers would amount to a staggering $1.15 trillion in total value. Meeting this demand requires a concerted effort to bolster domestic production.

Currently, 70% of the U.S. demand for distribution transformers is met by domestic production. To address the increased demand, it's essential to maintain a balanced mix of imports and domestic supply. Modeling projections suggest that $808 billion worth of transformers will be domestically produced, stimulating economic activity across various sectors.

Economic Implications and Opportunities

The production of distribution transformers in the U.S. presents substantial economic opportunities and implications. According to IMPLAN data, this endeavor would generate significant value added to the GDP, amounting to over $1 trillion. Moreover, it would contribute approximately $81 billion in state and local tax revenues and $151 billion in federal tax revenues.

This surge in production would also create ripple effects throughout the economy, stimulating demand across diverse industries. From copper rolling and steel manufacturing to transportation services and healthcare, numerous sectors stand to benefit from increased transformer production. The multiplier effect of this economic activity amplifies its overall impact, fostering growth and prosperity across the nation.

Looking Ahead

As we navigate the evolving landscape of distribution transformer demand, it's crucial to remain vigilant and adaptable. Factors such as price fluctuations and technological advancements can significantly influence industry dynamics over time. Continuous analysis and strategic planning are essential to capitalize on emerging opportunities and mitigate potential challenges.

In conclusion, the United States is facing a pressing need for distribution transformers to meet surging demand. By prioritizing domestic production and leveraging the multiplier effect of the transformer manufacturing industry, we can unlock substantial economic growth and resilience. This undertaking not only strengthens our infrastructure but also paves the way for a more prosperous and sustainable future.

.png?width=80&name=IMPLAN_Logo_Print-Vector_NEW%20(2).png) Copyright 2025

Copyright 2025